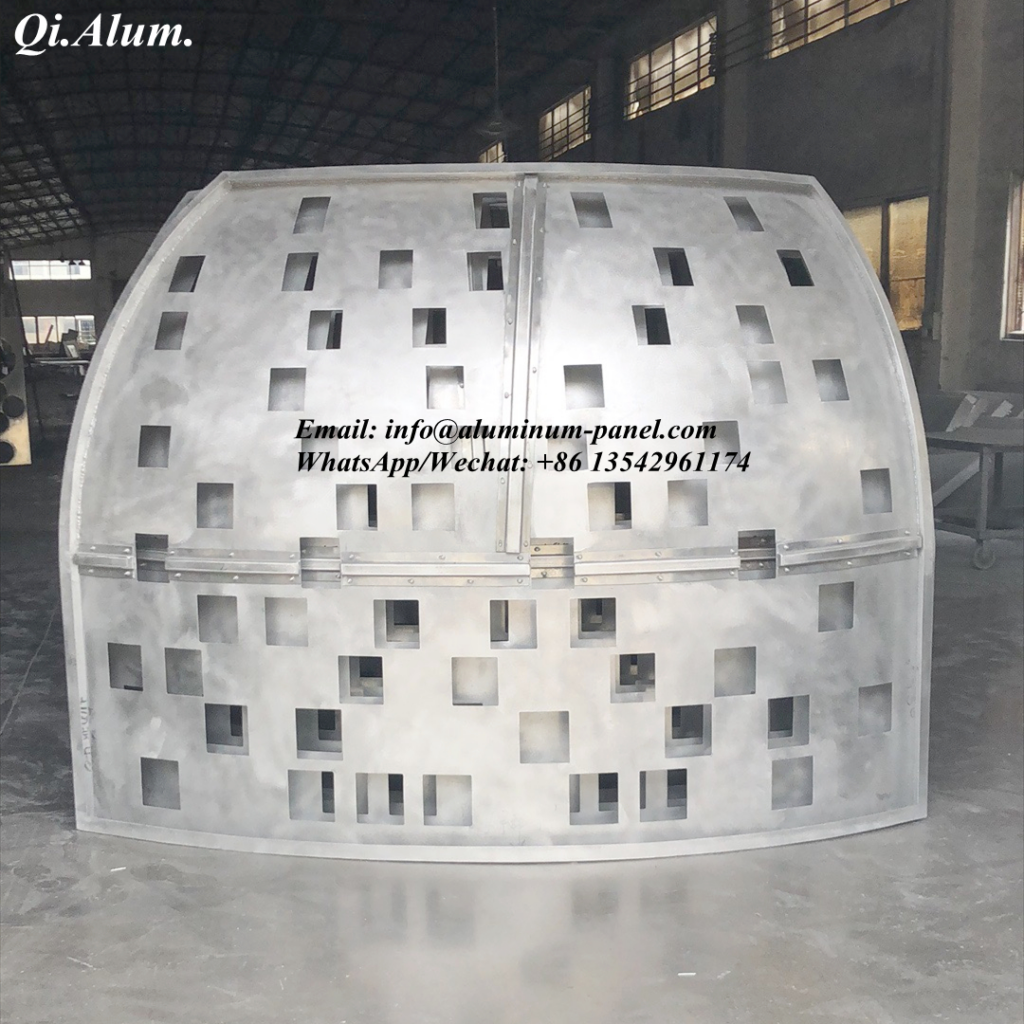

1, curved aluminum panel by the older aluminum alloy is the secondary material, after cutting, folding, bending arc, welding, reinforcement, grinding, painting and other processes and a variety of types of processing technology processing completed in my opinion metal curtain wall products.

2. In my opinion, aluminum panel is the second main choice for building exterior decoration. Compared with non-porcelain, glass, aluminum plate, honeycomb plate, marble and outer decoration materials, this kind of unique inheritance but has broad development space in my opinion.

3, curved aluminum panel and characteristics determined the production process for them in a word in my opinion unusual.

4, and can be described as simple: in accordance with the drawings and design of the curved do this module, will use the module to open aluminum, and then welding, grinding, polishing, cleaning, painting, this two curved aluminum panel do also come out.

5. curved aluminum panel series products are frequently used in building lobbies, airports, stations, important public facilities, stadiums, ethnic buildings and high-end buildings.

aluminum panel. A hyperbola is when two different arcs overlap on the same plane. That is, you draw a two-radius arc from the center of a different circle. curved aluminum panel price is usually much more expensive than ordinary aluminum panel, many people do not know why the curved aluminum panel price is higher than ordinary aluminum panel price? In fact, the price of curved aluminum panel is not only affected by the price of aluminum ingot, but also affected by the processing surface and surface treatment difficulty.

Curved aluminum panel refers to aluminum panel products with different surface shapes in different directions and radii based on the same point. So the same thickness and paint of the curved aluminum panel, because of modeling reasons, usually more expensive than ordinary aluminum panel, even some times as high.

It is also determined by the processing of curved aluminum panel. The center of the curved aluminum panel is located on a different side from the surface. Slight changes in radian and radius require a lot of adjustment. Aluminum panel machinery and processing master requirements are also very high, these factors are indispensable. The processing steps are mainly divided into two parts:

1. Sheet metal processing: mainly used for the “general direction” processing of curved aluminum panel. In the process of processing, the use of cutting, folding, arc, welding, polishing and other processes to process the aluminum panel into the shape and size required by the construction, determines the radian and shape of the aluminum veneer and other important parameters.

2. Spraying: Spraying is to spray paint on the processed aluminum plate. There are two kinds of sprays. One is manual spray, the other is machine spray. Mechanical spraying is generally only applicable to ordinary aluminum panel, but this kind of aluminum panel is rarely used in practice, most of the domestic enterprises are used by manual spraying. One advantage of manual painting is that colors can be selected, regardless of quantity. Before spraying, curved aluminum panel should be treated before spraying in order to achieve good results.

3. When painting with this unique shape of curvedaluminum panel, ordinary electrostatic spray painting can not be used, but manual spraying is required. In this way, the uneven painting layer on the surface of the aluminum panel can be prevented, and the problem of affecting the decorative effect can also be prevented.

Therefore, it is not surprising that the curved aluminum panel is difficult to manufacture, the processing process is complex, the price of aluminum panel is high, and the processing cycle is long.