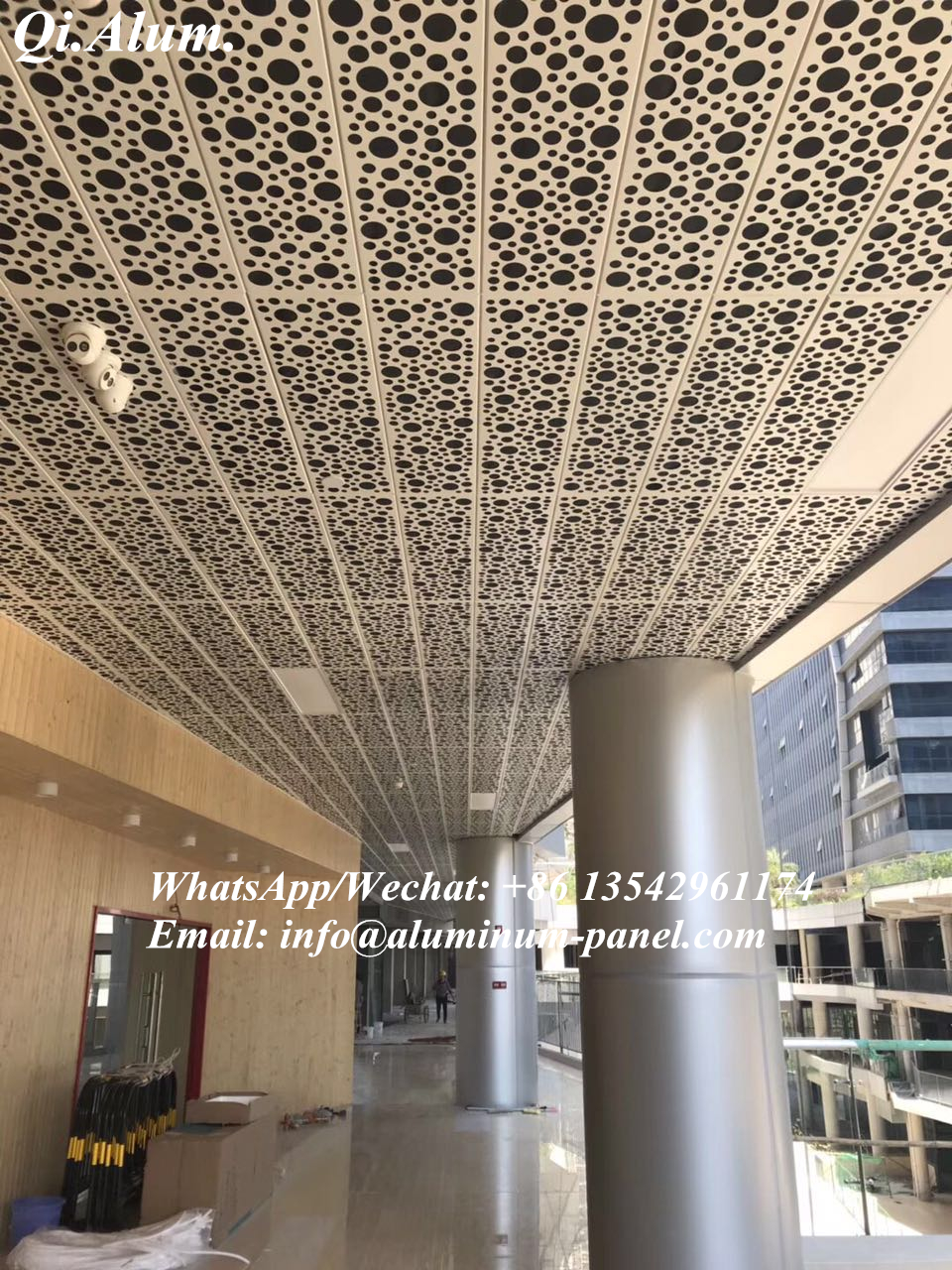

Restaurant interior ceiling decoration with aluminum perforated metallic painting panels

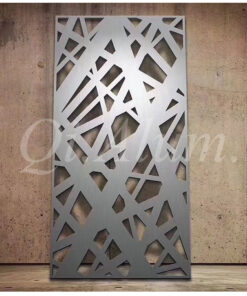

Aluminum perforated panel ceiling is made of aluminum solid panel with CNC cutting or hole punching process.it’s different from the aluminum clip-in/lay-in aluminum ceiling system.Aluminium perforated panell ceiling is to use aluminium alloy material to make and become, its craft also is decided according to actual situation.Standard square ceiling is made of precision mold, and special-shaped aluminum ceiling is processed by material cutting, leveling, cutting Angle, bending molding, spraying and other processes.Aluminium ceiling is applied now very extensive, domestic outfit, tooling can choose.

In the aluminum ceiling production and sales industry, there are many different names for hole punching aluminum plates, such as perforated aluminum plates, aluminum alloy perforated plates, perforated aluminum ceilings, perforated aluminum gussets, and perforated aluminum veneers. The reflected sound of hole punched aluminum ceiling is very small. When sound waves incident on the surface of porous materials, they will cause air vibration in the pores. Due to friction resistance, air viscosity resistance and heat conduction, a considerable part of sound energy will be converted into heat energy, which will play the role of sound absorption. And the hole punched aluminum ceiling plate has good air permeability,which is a typical sound-absorbing and breathable aluminum ceiling.

Advantages:

Nice-looking and utilitarian

1-Perfect surface flatness and smoothness.

2- Bright and beautiful, good texture,

3- Good decorative effect,

4-Easy to meet the requirements of the designer

Contact: