With continuous advancements in material innovation and process technology, the performance and precision of 3D aluminum panels have been significantly enhanced.

One of the key influences on the development of 3D aluminum panels is the emergence of new types of aluminum alloy materials and advanced processing techniques. The constant evolution of material science and process technology has paved the way for improved performance and processing accuracy of 3D aluminum panels.

Moreover, the application of digital manufacturing technologies, such as computer-aided design (CAD), computer-aided manufacturing (CAM), and 3D printing, has brought higher flexibility and precision in the design and production of 3D aluminum panels. This has accelerated the product development cycle and allowed for more efficient manufacturing processes.

Furthermore, the increasing emphasis on lightweighting and energy conservation in industries such as automotive and aerospace has made aluminum alloys the preferred alternative to traditional materials. The outstanding lightweight properties of aluminum alloys make them highly sought-after, thus driving the demand for 3D aluminum panels.

In addition to this, there has been a growing demand for customization and personalization in consumer products. The development of 3D printing technology has made it easier to achieve customized production of aluminum panels, thereby meeting the diverse market demands.

Last but not least, the integration of the complete supply chain and the application of intelligent manufacturing play a pivotal role in the production of 3D aluminum panels. Streamlining the entire supply chain and adopting intelligent manufacturing can improve production efficiency, reduce costs, and enhance product quality.

As the market continues to evolve, it is crucial for businesses to keep up with these trends and adapt their strategies accordingly. I hope the information provided proves useful in understanding the factors influencing the development of 3D aluminum panels.

FAQ:

Q:How about customized?

A:Our professional R&D team can meet your OEM/ODM requirement.

Q: How about your quality guarantee ?

A: For all our products, we have certificate and product quality test report, if there is any lost caused by us, we will make compensation.

Q : How about sample ?

A : Free sample can be sent within 5 days after confirmation, but shipping cost will be afford by the buyer, it will be refund when order.

Q : Do you have any successful customer example?

A : Yes, please contact us for more details. And the supplier of Asian City in Guangzhou and Guangzhou Baiyun Airport.

About us:

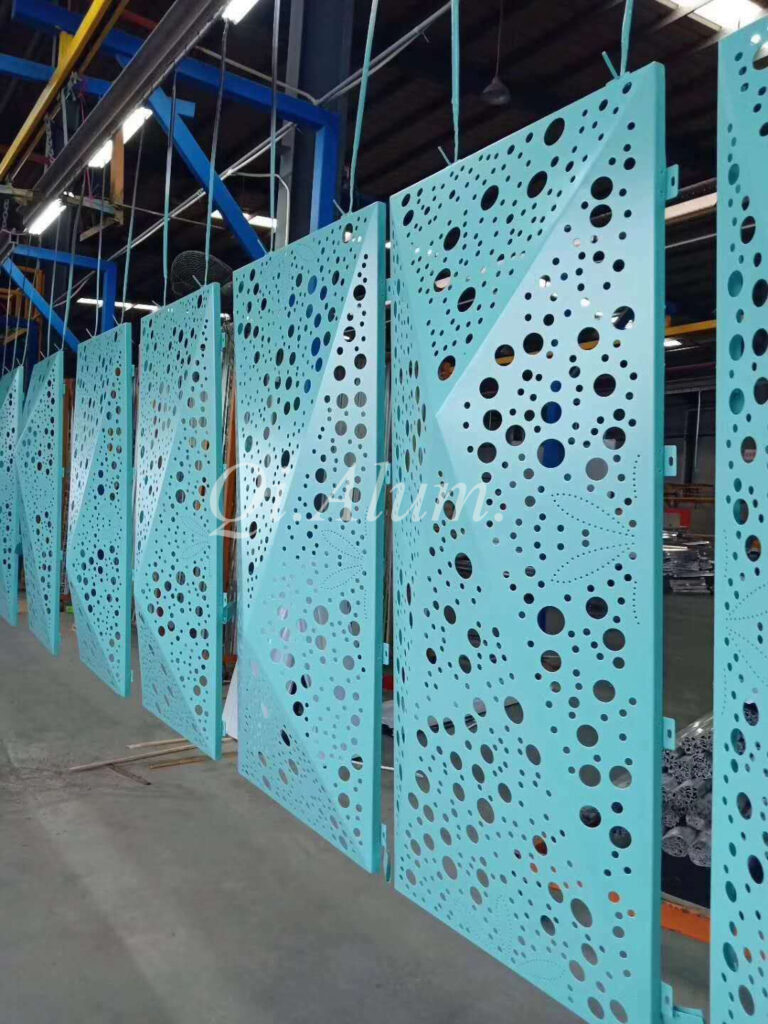

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience,We are manufacturer of fabricating aluminum perforated sheets, aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design, fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price, globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!