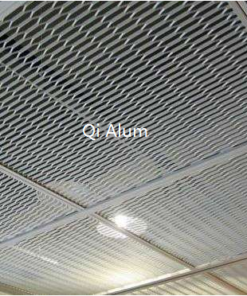

Decorative aluminum expanded mesh fireproof aluminum perforated mesh for screen

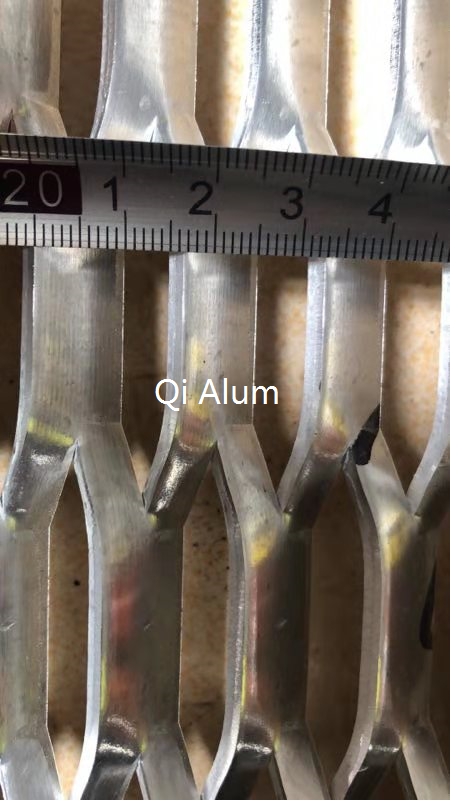

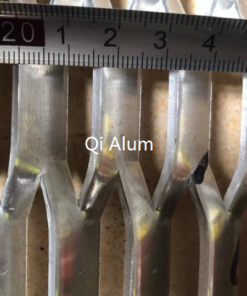

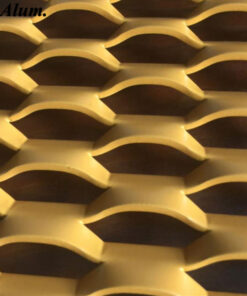

Coating aluminum mesh and panel, which is combined with the roller coating technology with digital printing technology. On one side or two sides of aluminum mesh or panel, make the pre-treatment of degreasing, cleaning, conversion film, using high-quality polyester or PVDF paints, passing many times coating and baking.The aluminum expanded mesh uses the high quality aluminum panel as the raw material, through the advanced numerical control machine processing; the aluminum plate punching net (perforated aluminum panel) may carry on the pressing type, the bending, the winding and so on deep processing treatment, the surface may carry on the spraying treatment, the color may according to the customer needs to choose.

Expanded Aluminum panel is both versatile and economical. It is more cost-effective compared with perforated metals. Because it is slit and expanded, it creates less materials waste during manufacturing, thus you don’t have to pay for the material loss in the production process. Aluminum expanded sheet has excellent strength to weight ratio and a number of patterns to choose from.Expanded Sheet allows easy passages of sound, air and light, with open areas ranging from 5% to 70%. It is available in most material types and finishes, and highly versatile for producing different shapes, cutting, tube and roll forming.Expanded Metal Sheets are supplied in Micro Mesh, Standard Rhombus/ Diamond Mesh, Heavy Raised Sheet and Special Shapes.

Advantages:

1.High plasticity, can be made as flat,camber or spherical shape.

2.Wide range of colors

- Excellent in weather fastness and corrosion resistance.

- Good fireproof and waterproof property.

- Even coating, various colors.

6.Easy to process ,easy to maintain.

Contact: