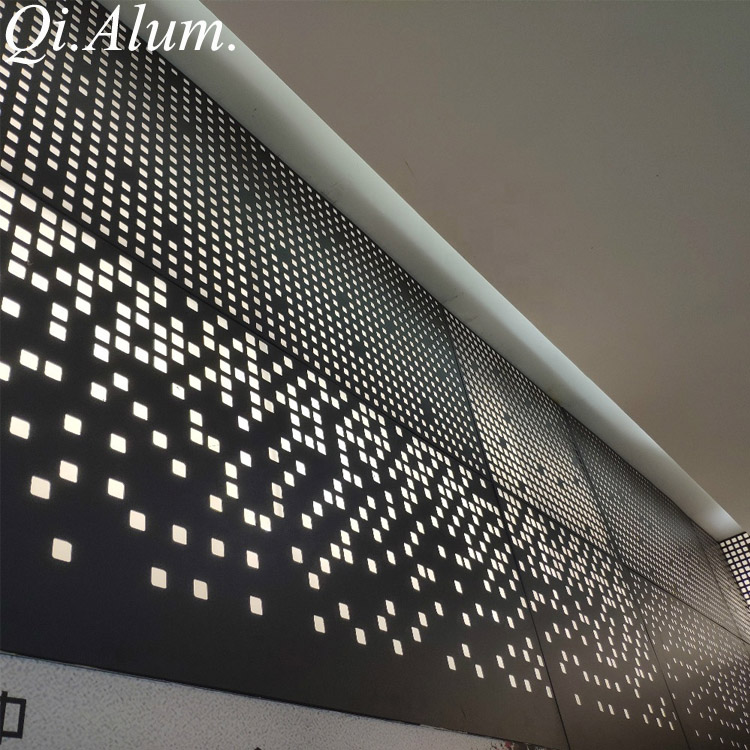

Aluminum metal punched regular hole punching perforated screens anti-corrosion metal sheet

The punched aluminum sheets adopts high-quality 1100, 3003 and 5005 solid aluminum alloy panels as the base material. The surface coating is divided into PVDF spraying, powder spraying, polyester paint spraying and PVDF pre roller coating.Hole Punched aluminum apnel is a type of aluminum panel that focuses on punching style. The punching shape of the hole punched aluminum sheet is an important parameter that determines whether the appearance of the hole punched aluminum sheet is beautiful. However, punched aluminum sheet is mainly composed of three parts: punching shape, punching rate and the color. The difference between punched aluminum sheet and ordinary aluminum sheet is that punched aluminum sheet is hole punched and has no sealing property.this make thee building can breath,with more longer service life.

Aluminum hole punching panels widely used in facade ,ceiling,balcony decoration,with the rectangular hole, square hole, rhombic hole, round hole, hexagonal hole, cross hole, triangular hole etc,and the processing technique of punching,welding,and bending,now more and more popular in the architectural decoration industry .The hole punched aluminum panels installation method is very simple,they are fixed with anchor bolts in strong system, this gives the building with very good impact strength.

Advantages:

1.Protect from strong sun light,

2.fire proof,

3.anti-humidity,

4.sound absorption,

5.simple installation,

6.low maintenance cost,

7.flexible combination,

8.fashion design,

9.various colors,

10.deluxe outlook,

11.environment-friendly.

Contact: