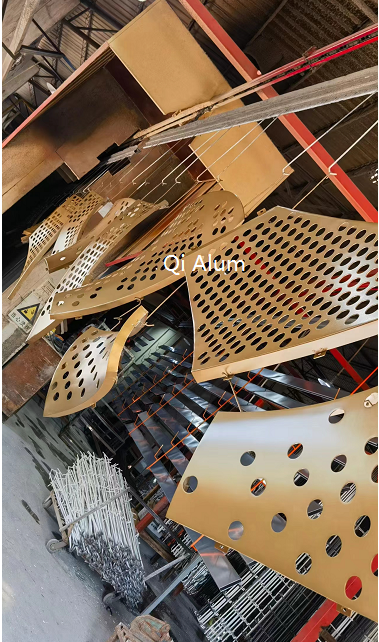

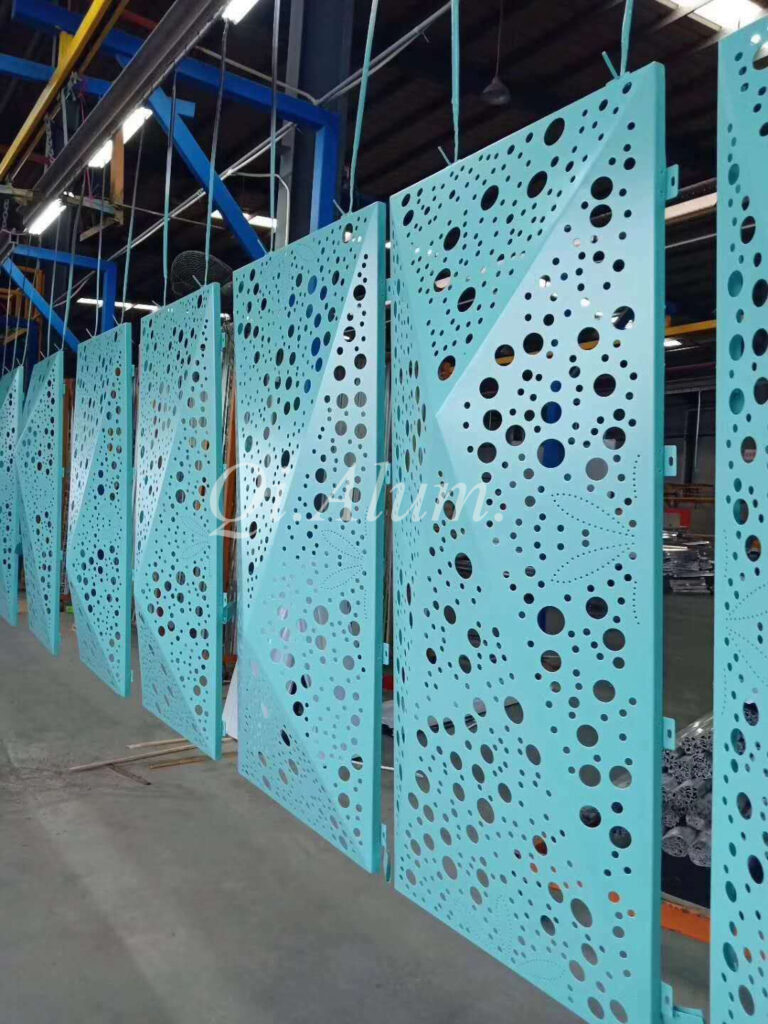

3d custom design CNC cutting perforated facade aluminum cladding

3D design CNC cutting perforated panel is outstanding at the visual impact when use for the facade decoration.The 3D designed perforated panel is usually made of welding,bending,folding the plain panels with perforated hole ,it also called 3D perforated plate, 3D punched plate, and is sheet metal that typical has been mechanically stamped or punched using specialized tooling in high-speed punching machinery, to create a pattern of holes,slots or decorative shapes.

The aluminum wall 3D design CNC cutting perforated panel is also called the aluminum cladding, cladding panel, and aluminum solid sheet. It’s processed from high-quality aluminum plates. With a variety of processing procedures such as of shearing, punching, bending, arc-rolling, welding, burnishing, riveting assembling, rib assembling, polishing and spray coating, then the aluminum plate processes into wall panel, the material of metal curtain wall/ facade.

Features:

Light weight, good rigidity, high strength and reasonable structure. Anti-wind deformation performance, anti-rain water leakage and anti-air oxidation, seismic performance can meet structural design requirements;

good processing performance, can be processed into a plane, curved, spherical and other complex shapes, fully meet the various design requirements;

the color selection range is wide, the decorative effect is good, it is easy to meet the designer’s color requirements;

The surface coating has strong weather resistance and the color remains unchanged;

good fire performance, excellent corrosion resistance;

The construction and installation is flexible, convenient, fast and easy to maintain;

not easy to be contaminated, easy to clean and maintain;

can be recycled and recycled, is environmentally friendly

Application:

Landscape architecture

building facades

curtail wall

Exterior decoration / protection

Interior decoration / protection

Contact: