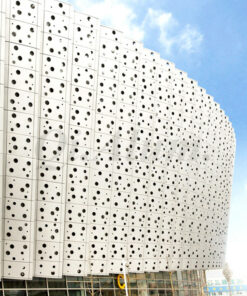

2.0mm Aluminum Hole Punching Metal Perforated Exterior Wall Cladding Panel For Facade

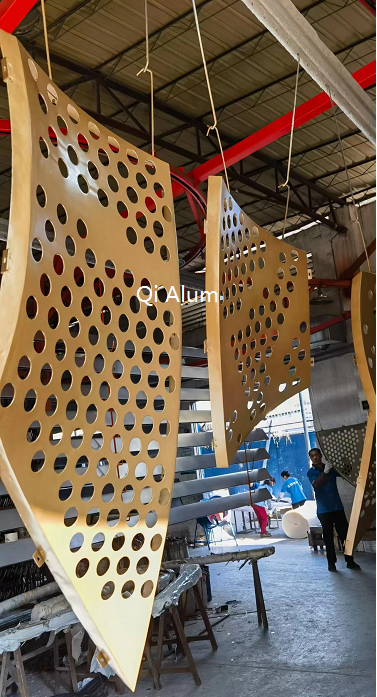

Hole Punching aluminum screen is a refined product of aluminum sheet. Its stable characteristics provide a variety of types of choices for the processing of the panel surface, such as bending, welding, arc bending, etc., with a variety of types, it can adapt to a variety of more complex shape designs. Its good processing performance makes it convenient for production personnel to process it into various forms of shapes.

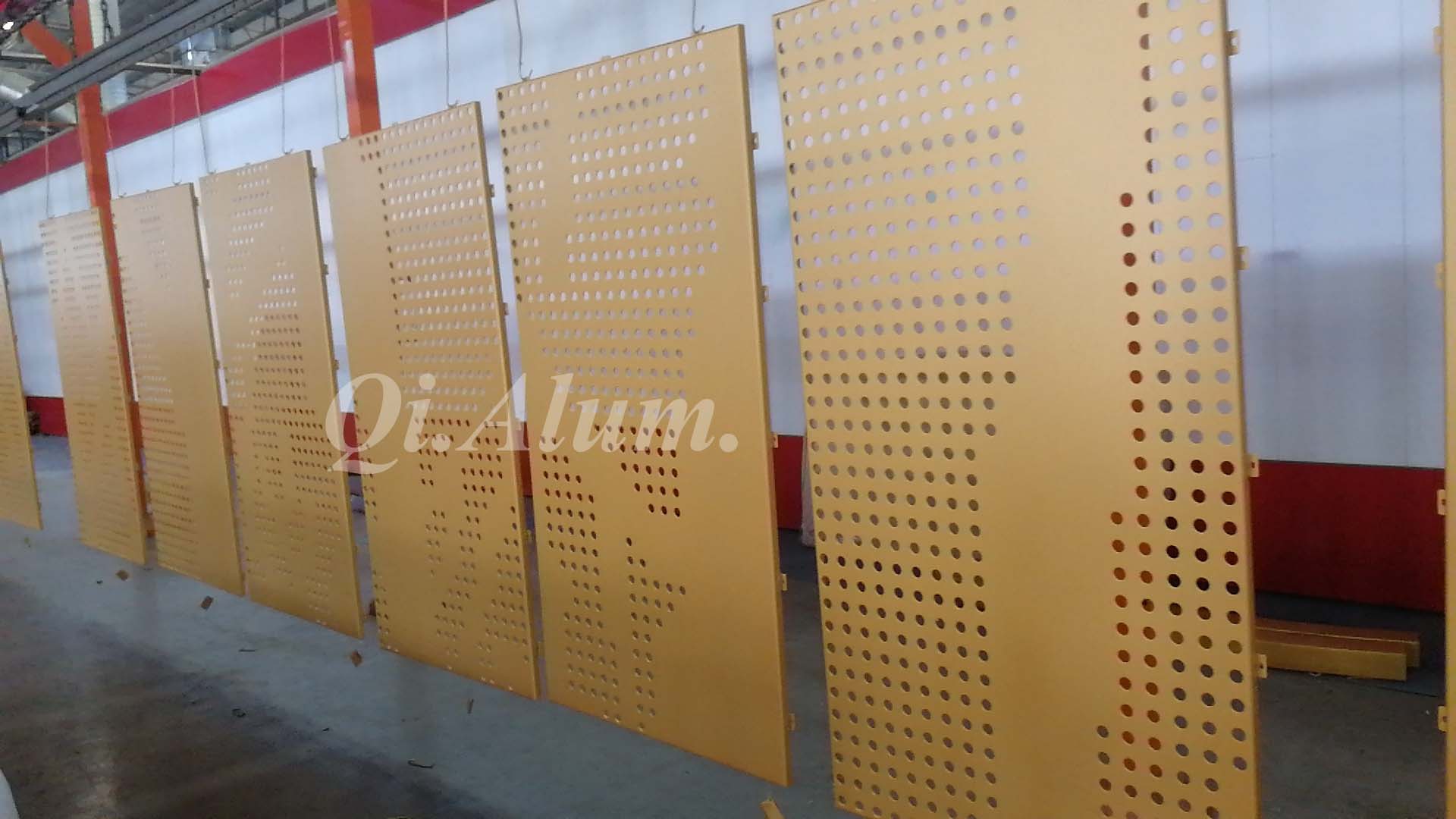

Perforated hole punching aluminium cladding with PVDF coating, the perforated Aluminum panels are very well weather-resistant, corrosion-resistant and discoloration-resistant. This helps the building to stay durable color and clean look. The personality design that accepts your ideal, can complete your ideal and design completely, make different product pattern.

The punched aluminum sheets adopts high-quality 1100, 3003 and 5005 solid aluminum alloy panels as the base material. The surface coating is divided into fluorocarbon spraying, powder spraying, polyester paint spraying and fluorocarbon pre roller coating. The punching shape of the hole punched aluminum sheet is an important parameter that determines whether the appearance of the hole punched aluminum sheet is beautiful. However, punched aluminum sheet is mainly composed of three parts: punching shape, punching rate and the color. The difference between punched aluminum sheet and ordinary aluminum sheet is that punched aluminum sheet is hole punched and has no sealing property.this make thee building can breath,with more longer service life.

Advantages:

1) Used as decorative mesh for building outer wall.

2) Visibility and colorful.

3) Rainstorm or insolation won`t hurt.

4) Aluminum won`t get rusty.

5) Anti-corrosive.

6) Weight is light enough for outer wall hanging.

Contact:

-247x296.jpg)

-247x296.jpg)