Many people do not know how to deal with the oxidation of aluminum sheet mesh. Today, the aluminum plate mesh manufacturer customized to tell you how to prevent it from being oxidized. In packing, it is important to control the temperature and humidity. Therefore, the humidity of the packaged wood shaft and box plate should […]

Category Archives: Uncategorized

The surface treatment technology of anodized aluminum plate is different from ordinary painting technology. It passes through the current to make the conductive acid electrolyte electrolytic, so that the aluminum metal surface of the anode is oxidized, and a thick and fine protective film of alumina is naturally grown on the aluminum surface. This layer […]

The characteristics and advantages of hooking board: 1.General purpose: It can make the aluminum plate net and aluminum honeycomb plate as the main curtain wall to hook up the structure to install the ceiling. 2, simple structure: this structure is a one-way parallel keel hook type structure, so that the hook plate installation is more […]

Anodized wave molding profile aluminum plate: Aluminum plate to do anodic oxidation surface treatment, can do satin oxidation, drawing oxidation, embossing oxidation, surface treatment is diverse, beautiful, color can be chosen at will, fully show the artistic effect of the design, the product after anodic oxidation coloring to do gold, can replace the gold foil […]

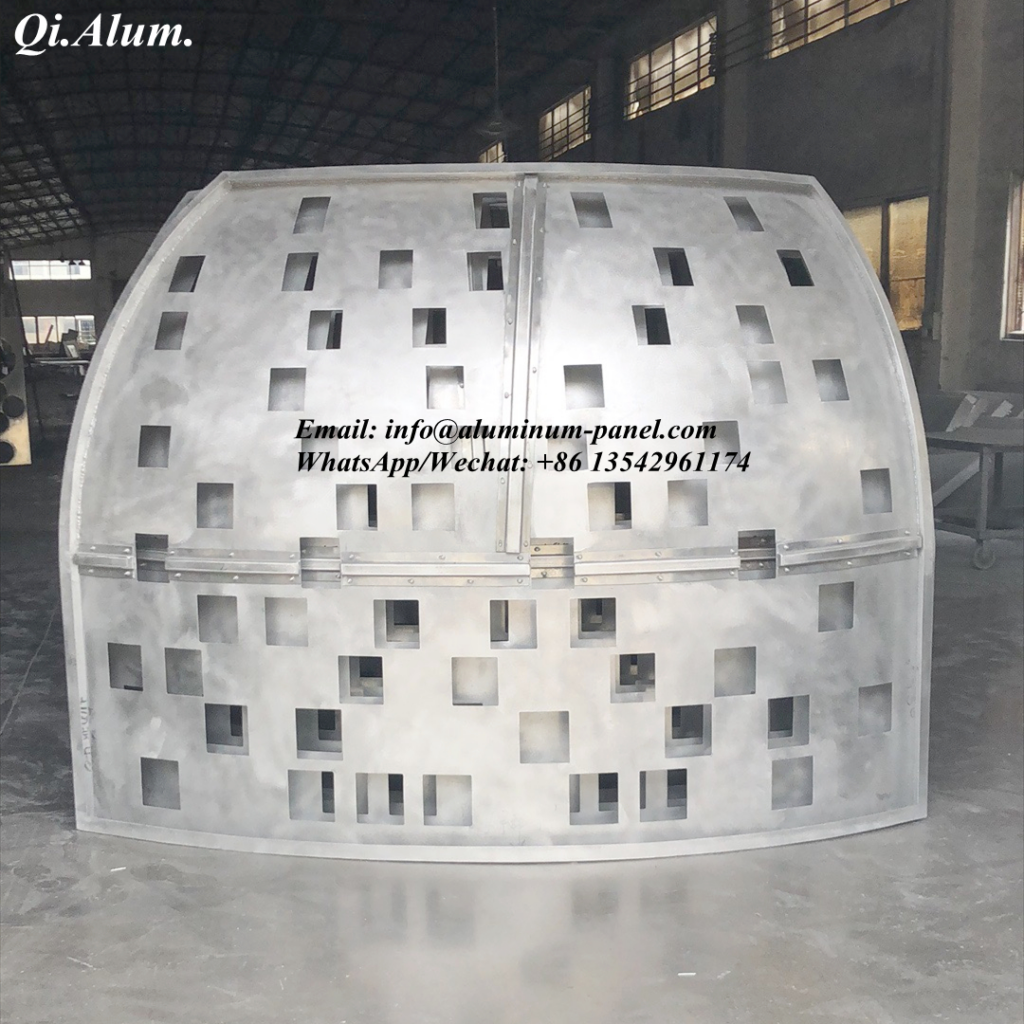

Perforated metal plate, as the name suggests, is based on a variety of metal plates as the base material, through mechanical punching, CNC cutting and other modern processing technology, the plate according to a certain law of various holes, forming a special texture texture or pattern. After metal plate perforation can also be according to […]

Metal composite plate can play the respective advantages of component materials, achieve the optimal allocation of each component material resources, and achieve the performance requirements that a single metal can not meet. In addition to its industrial applications, it is also widely used in various projects with its excellent appearance and performance. What is metal […]

Aluminum profiles, aluminum rods through hot melting, extrusion, so as to get different cross-section shape of aluminum materials. The production process of aluminum profile mainly includes three processes: casting, extrusion and coloring. Among them, the color mainly includes: oxidation, electrophoretic coating, fluorocarbon spraying, powder spraying, wood grain transfer printing and other processes. We all know […]

1, curved aluminum panel by the older aluminum alloy is the secondary material, after cutting, folding, bending arc, welding, reinforcement, grinding, painting and other processes and a variety of types of processing technology processing completed in my opinion metal curtain wall products. 2. In my opinion, aluminum panel is the second main choice for building […]

special-shaped aluminum panel is different from conventional aluminum panel molded board, it is according to the design needs of the conventional aluminum panel after multiple machine bending, stretching, artificial grinding to form different shapes, different shapes of aluminum panel. Special-shaped aluminum panel production process is complex, high technical requirements, the cost is also higher than […]

Aluminum carved panel processing appearance, wood pattern rich, realistic effect, clear texture. Fire resistance: corrosion resistance, moisture resistance, hardness and strength are solid wood floating method compared to rust prevention, damage prevention, UV protection. Processing hollow aluminum panel long service life, can keep 10-15 years no color, no deformation. Strong plasticity, can be processed into […]