Specification

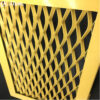

| Our Products | Perforated metal mesh |

| Size | 1) Thickness: 0.3mm-10mm 2)Mesh Length: 1.8m – 2.44m 3)Mesh Width: 0.8m – 1.22m 4)Perforated area percent: from 10% to 70% |

| Hole forms | Diamond,round, square, triangle, hexagon etc |

| Surface Treatment | Electric galvanized, Hot dipped galvanized, PVC coated, oxidation treatment etc |

| Characteristics | Corrosion resistance, ageing resistance, durable, etc. |

| Packing | 1.LCL: packed with plastic film then on the pallets 2.FCL: Nude packing 3.Other special package according to customers’ requirements. |

Finishing Types

Finishing metal is a demanding task that can make a crucial difference in the appearance and durability of the final product. For the best results, we recommend that you rely on our finishing services. We offer many types:

Anodizing

Anodizing is an electrolytic process used to increase the thickness of the oxidation that naturally forms on the surface of many metals. Typically used with aluminum, anodizing takes advantage of the inherent properties of aluminum oxide to create a hard, corrosion-resistant surface. Anodized aluminum has an attractive metallic sheen, and can be either clear or dyed in various colors.

Clear Coat (Anodizing)

Clear Anodizing is a process that creates a thin layer of aluminum oxide coating on aluminum metal without the use of dyes or pigments.

E-coating

E-coating is an electropainting or electrophoretic lacquering process to deposit a paint or lacquer coating.

Electrogalv

The most common galvanizing method is electrochemical deposition of the zinc alloy. Because this process creates a relatively thin layer of galvanization, painting is generally recommended for outdoor applications to provide the best corrosion resistance.

Hot-dip galvanization

The part is passed through a molten zinc bath, providing a much thicker coating of zinc at a somewhat higher cost compared to electrogalv. Hot-dip galvanization produces a characteristic crystallization pattern or “spangle” on the surface.

Paintgrip

Galvanized steel that is dipped in a phosphate bath for additional corrosion protection and to improve paint adhesion.

Paintlock

Galvanized steel that has a zinc coating which is electronically deposited and then chemically treated to improve adhesion of paint or powdercoat finishes.

Plating

Plating refers to a number of processes for depositing a coat of one type of metal on the surface of another. Plating materials can be chosen for their beauty, corrosion resistance, hardness and a variety of other purposes. Examples include gold, silver, chrome, zinc, tin, cadmium and many others. Plating techniques also vary, and include both electroplating and electroless methods. Contact us to discuss the right plating material and method for your project.

Powder Coating

Powder Coating is an electrostatic process for applying a dry, powdered material such as polyester, polyurethane or epoxy. The piece is then heat-cured to flow the material together and create the final finish. Powder coating is generally thicker and more durable than paint, although the cost can be somewhat higher depending on the project. A broad selection of colors is available.

Large sheets and coils, corrugated pieces, finished components and even special designs – Accurate Perforating can apply virtually any finish to perforated part, as long as we determine that the finish is appropriate for the material. Contact us to discuss your finishing ideas and questions.

COMMERCIAL TERM

|

Place of Origin

|

foshan, guangdong, China

|

|

Material

|

AA1100, AA3003, AA5052

|

|

Packing Details

|

Double layer packaging-protective film and bubble film, to ensure that the product won’t cause scratches on the safety of transportation.

|

|

Hole shapes

|

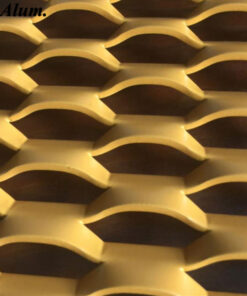

Diamond Holes, Hexagon Holes, Round Holes ,Scale Holes…

|

|

Surface Treatment

|

PVDF Coating or Powder Coating

|

|

MOQ

|

100 square meters

|

|

Production capacity

|

80000 Square Meters/per month

|

|

Leadtime

|

Shipped in 30-45 days after payment

|

|

FOB Port:

|

guangzhou, shenzhen

|

|

Delivery Clause

|

FOB/CIF

|

|

Payment Term

|

T/T, L/C, D/A, D/P, Western Union, MoneyGram

|

|

Note: can be customized according to the given specifications from clients .More requirements and specification, pls feel free to contact with us.

|

|

Aluminum metal expansion mesh with metal frame frame to form a transparent ceiling surface, the system can choose dark bone mode or open bone mode;

1 simple structure, this structure is one-way parallel keel hook type structure (specific reference to the “Z” series), aluminum gusset ceiling installation structure, simple and stable, some structures have special windproof function;

2, connection mode, can choose the secret mode and open mode connection mode; Engineering aluminum ceiling ceiling keel firm well shaped structure combination, smallpox aluminum gusset plate installation and disassembly is easy, the surface is very smooth;

3, transparent grid engineering aluminum ceiling, simple and beautiful, overall, has good sound-absorbing decoration function, for the occasion of strong sound-absorbing effect, such as concert hall, bar, dance hall, etc., can be built in the grid ceiling surface of sound-absorbing moisturizing cotton, can create the sound-absorbing effect.

Why us:

You have our highest priority and prompt attention!

1. Your inquiry will be replied within 24 hours.

2. Our professional R&D team can meet your OEM/ODM requirement.

3. Strict Quality Control to insure providing you high quality products.

4. Our After-sale dept could help you deal with any problems when you received our products.

FAQs

1)What about your packages ?

A:Inner EPE paper packing, exterior with wooden frame crate box.

We have been exporting lots of products to overseas,not any clients make any complains on our packages.

2)Is there any price difference between powder coating and anodising ?

A:No price difference between them.We recommend you to choose anodised finish if the house is near salt

salt water.

3)What is the delivery time?

A:Normal 10-35days after received the deposit and confirmed all the details

About us

Foshan Qi Aluminum Decorative Materials Co.,Ltd, more than 12 years experience ,We are manufacturer of fabricating aluminum perforated sheets , aluminum solid panels, aluminum screen,aluminum facade decorative sheets, aluminum expanded mesh, aluminum ceiling with good quality and fast delivery for more than 10 years to export countries. Our factory production line includes 14 CNC carving/cutting machines, 8 mould punching machines with 120 sets moulds for hole punching, 9 CNC bending machines as well as accessories assembly machines. We have two coating lines with powder coating, and PVDF coating with working 24*7 hours, cooperating with Jotun, PPG, Akzon brands . We had done projects in Dubai, Qatar, Bahrain, Kuwait, Tajikistan, Tanzania, Maritius, Singapore, Malaysia, Australia, Canada, America and so on. Our monthly supplying is about 80000 sqms for inside and outside market. Our projects covers five star hotel, high end villas, school, campus, metro station, airport, office building, shopping mall and some other goverment projects. We can provide design ,fabrication and installation one stop service for your projects. High precision, quality guarantee, affordable price , globla delivery and considerate service is our basis. We accept OEM/ODM business. We are the experienced specialist on facade solution decoration!!!