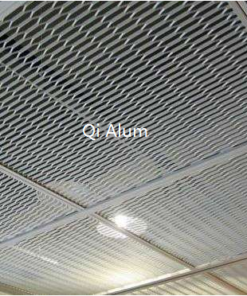

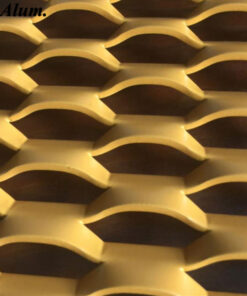

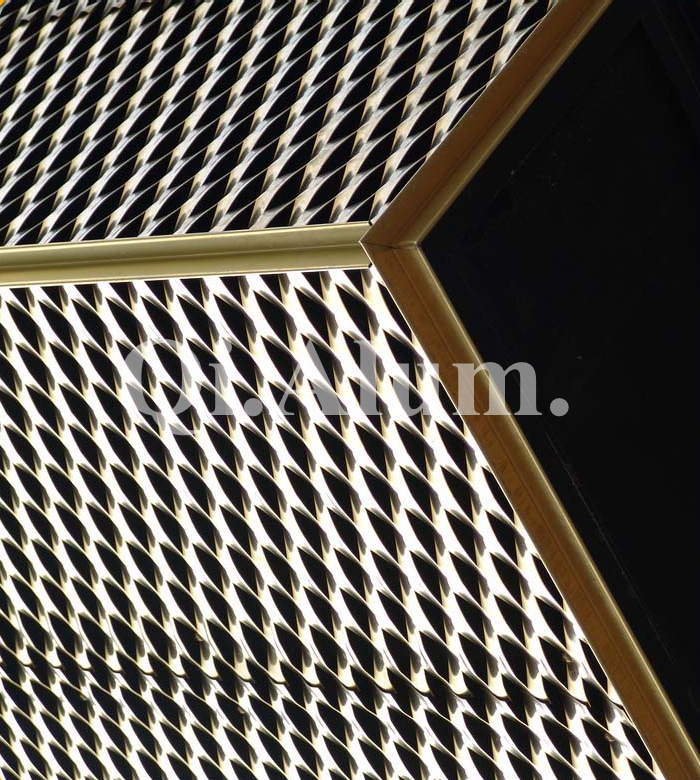

Aluminum Expanded Hexagon Hole Mesh Expanded Aluminum Metal Mesh Facade Cladding

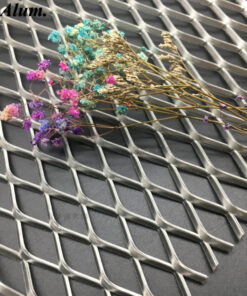

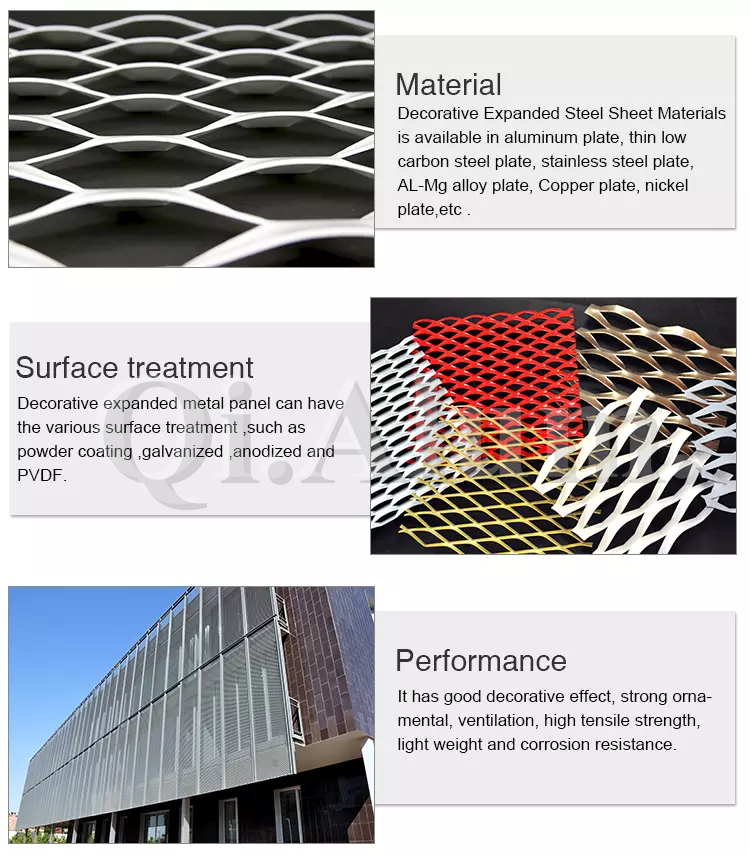

The manufacturing process of aluminum expanded metal mesh is different from that of ordinary aluminum perforated panel. Ordinary aluminum perforated panel needs to go through more than ten processes, such as cutting, bending, polishing, etc., while the aluminum expanded metal mesh is different. Its processing process is to design parameters through a data machine. The most important thing here is the setting of parameters and the use of panel size. The aluminum expanded metal mesh will has higher requirements on the base material, which is too hard, Or the raw material is too soft will lead hard to process the ideal aluminum mesh panel.

After the screen mash is finished, it usually needs to be framed with different thicknesses. Its process is like a screen, which needs to be fixed and locked; This step is more difficult.Expanded Aluminum panel is both versatile and economical. It is more cost-effective compared with perforated metals. Because it is slit and expanded, it creates less materials waste during manufacturing, thus you don’t have to pay for the material loss in the production process.

Advantages:

1.Protect from strong sun light,

2.fire proof,

3.anti-humidity,

4.sound absorption,

5.simple installation,

6.low maintenance cost,

7.flexible combination,

8.fashion design,

9.various colors,

10.deluxe outlook,

11.environment-friendly.

Contact: